|

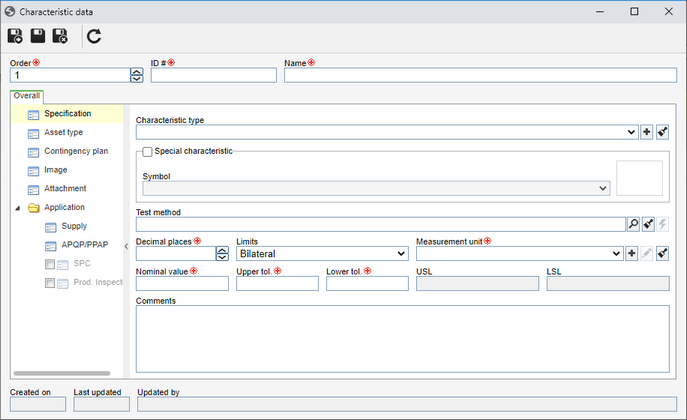

To add a characteristic to the item, click on the arrow next to the  button of the Characteristic section, on the item data screen, and select the Variable option. At this point, the characteristic creation screen will be displayed according to the selected option. Fill out the following fields: button of the Characteristic section, on the item data screen, and select the Variable option. At this point, the characteristic creation screen will be displayed according to the selected option. Fill out the following fields:

Variable characteristic

Field

|

Order

|

This field will be filled in with the number of the sequence in which the characteristic will be displayed in, but it is possible to change it.

|

ID #

|

Enter a number or code that identifies the characteristic.

|

Name

|

Enter a name for the characteristic.

|

Save the record. At this point, according to the characteristic type, the sections will be available to be filled out:

Field

|

Characteristic type

|

Select the type that classifies the characteristic.

|

Special characteristic

|

Select this field if it is a critical or important characteristic of the item. In the Symbol field select the symbol that will identify the characteristic.

|

Test method

|

Select the document with the test method to be applied to the item characteristic. In order for this resource to be available, the organization must have an active license key in SE Document.

|

Decimal places

|

Enter the number of decimal places that may be used for the values related to the characteristic. The amount may vary between 0 and 8 decimal places.

|

Limits

|

This field will only be displayed for variable type characteristics. Enter the limits for the tolerances:

▪Bilateral: This field is displayed for variable type characteristics. It will allow entering the upper and lower tolerances. ▪Unilateral up: It will allow entering only the upper tolerance. ▪Unilateral down: It will allow entering only the lower tolerance. ▪Reference dimension: It will allow entering a reference dimension for the characteristic in question. |

Measurement unit

|

Select the unit that will be used in the measurement of the characteristic.

|

Nominal value

|

Enter a round or approximate value for the characteristic, that is, the expected value for the characteristic.

|

Upper tolerance

|

Enter the upper tolerance (or uncertainty) allowed for the characteristic.

|

Lower tolerance

|

Enter the lower tolerance (or uncertainty) allowed for the characteristic.

|

USL

|

The system automatically enters the Upper Specification Limit according to the defined upper tolerance.

|

LSL

|

The system automatically enters the Lower Specification Limit according to the defined lower tolerance.

|

Comments

|

Use this field to enter comments about the characteristic.

|

|

Use this section to associate the asset types related to the characteristic. To do that, click on the  button and, on the screen that will be displayed, select the desired types. button and, on the screen that will be displayed, select the desired types.

|

Use the Contingency plan section to create all the measures to be taken if an unforeseen problem occurs in the item. Therefore, click on the  button to add a new contingency plan. On the new screen, enter an identifier and description for the contingency plan. button to add a new contingency plan. On the new screen, enter an identifier and description for the contingency plan.

|

In the Image section, an image for the characteristic must be selected. Click on the buttons next to the Image field to add a new image or delete the added image.

|

Use the Attachment section to associate the attachments related to FMEA. Refer to the Adding attachments section for further details on how to add and/or associate attachments.

|

In this section, it is possible to associate supplies with the item characteristic. This relationship will be displayed in the production inspection screen of SE Inspection. To make the association, click on the  button. On the screen that will be opened, enter the supply and its quantity. button. On the screen that will be opened, enter the supply and its quantity.

|

Use this section to configure the fields that will be pre-filled out while executing Control plan form through the SE APQP/PPAP component. To do that, fill out the following fields:

Field

|

Machine, device, jig, and tools for mfg.

|

Enter, in this field, the object that the control plan will be about. This field will only be available if, in the configuration of the general parameters in APQP/PPAP, option Enter machine in characteristic is selected.

|

Operation / Control

|

▪Evaluation/Measurement technique: Enter the evaluation/measurement techniques that will be used to evaluate/measure the characteristic. ▪Sample size: Enter the value/description regarding the size of the characteristic sample. ▪Sampling frequency: Enter the frequency with which the sample will be evaluated. ▪Control method: Enter the methods that will be used in the evaluation/measurement of the characteristic. |

Reaction plan

|

Enter the reaction plan that will be used as the result of the evaluation/measurement of the characteristic.

|

The procedures to fill these fields in depend on the configuration of the APQP/PPAP general parameters.

|

|

In this section, it is possible to manage and track the control characteristics of the item that will be measured and tracked in the SE SPC component. To do that, select the checkbox next to the SPC section. At this point, the tabs will be enabled, allowing them to be configured:

General

Field

|

# of readings

|

Enter the number of sample readings of the characteristic in question that will be collected. Remember that a sample is a set of items that will be collected from the batch to be analyzed. Then, after the entered quantity is exceeded, the system will no longer allow collecting the data.

|

Analysis team

|

Select the team responsible for analyzing the characteristic. The team must be created in the SE PDM component.

|

Data collection team

|

Select the team responsible for collecting data of the characteristic. The team must be created in the SE PDM component.

|

Frequency

Define the frequency of the collections. For that, fill in the following fields:

Field

|

Control time frequency

|

Select this option to indicate that the frequency between collections will be controlled. After that, select the control type that will be performed:

▪# of samples: For this control type, enter the number of samples and the time unit that will be used to control the frequency. Example: 3 samples per hour. ▪Interval: For this control type, enter an interval, that is, how often data collection will be performed. If the data collection is not performed in the defined interval, the event log will be automatically opened to enter an occurrence. |

Name

|

Enter how frequently the data will be collected, for example, every two lots, every operator change, among others. Remember that this field will only be displayed if the "Control time frequency" option is not selected, that is, when the frequency is not controlled.

|

Alarm

Configure the alarms that may be triggered when entering the values read in the data collection. Then, fill out the following fields:

Field

|

Non-conforming measurements

|

Select this option and, after that, enter the acceptable percentage from the specification limits. Non-conforming measurements aim at avoiding typing mistakes, by defining an acceptable range for input values. The system will not accept values that exceed the non-conforming measurements.

|

Evaluation ranges

Click on the  button on this tab to create the evaluation ranges of the characteristic. The evaluation ranges serve to manage the collected data by means of a chart. Fill in the following fields on the data screen that will be displayed: button on this tab to create the evaluation ranges of the characteristic. The evaluation ranges serve to manage the collected data by means of a chart. Fill in the following fields on the data screen that will be displayed:

Field

|

Name

|

Enter a name for the evaluation range.

|

Color

|

Select the identification color for this range in the evaluation range charts.

|

Lower range limit

|

Select the operator (>=, >) and the evaluation range start value.

|

Upper range limit

|

Select the operator (<=, <) and the evaluation range end value.

|

Reading types

Configure the reading types that will be applied to SE SPC for the characteristic:

Field

|

Actual reading

|

Select this field for the system to read the complete value. For example, if the reading value is 5.35, the system will consider 5.35.

|

Only decimal places for readings (values >= 0)

|

Select this field for the system to read only the decimals places of the value obtained in the reading. For example, if the reading value is 5.35, the system will only consider 35.

|

Variation based only on reference value

|

Select this field for the system to read only the difference between the reference value and the obtained value. For example, if the reading value is 5.35 and the reference value is 5, the system will consider 0.35.

|

Equation

|

Select this field for the reading to be based on an equation.

|

Attribute

Associate the attributes that will complement the readings of the characteristic. To do that, click on the  button and select the desired attributes. Refer to the Adding attributes section for more details on this operation. button and select the desired attributes. Refer to the Adding attributes section for more details on this operation.

Event log

Use this tab to configure the rules for the generation of the event log for the characteristic. By default, the rules configuration is inherited from the General parameters of SE SPC. Then, use this tab to configure the rules for the characteristic in question, if it requires a specific configuration for the generation of event logs.

|

To configure the inspection of the item characteristic, in SE Inspection, first, make sure to check the box next to the Inspection section. At this point, the tabs will be enabled, allowing them to be configured:

General

Sampling rule

|

Select which rule will be applied to the item characteristic readings:

|

Sampling plan

|

The sampling plan will be used in the readings of the item characteristics. This plan contains the necessary configurations for the system to remove a sample size from the receiving. Click on the  button, located next to the Rule field to perform a simulation of the sampling plan. Fill out the following information: button, located next to the Rule field to perform a simulation of the sampling plan. Fill out the following information:

▪Sampling plan: Select the sampling plan that will be used in the reading of the item characteristics: Simple, Double or Multiple. ▪Inspection level: Select the level of inspection that will be applied to the item characteristics. This level secures a relationship between the lot size and the sample size: oLevel 01: when the inspection costs are high. oLevel 02: normal statuses. oLevel 03: when the inspection costs are reduced. oLevels S1 to S4: when the cost of destructive testing is high for small samples or large tolerated risks. These levels can be considered adequate when using repetitive processes by a good quality supplier. ▪Inspection type: Select the regime that establishes the severity of the characteristic inspection of the item: Reduced, Normal or Tightened. ▪AQL: Select the acceptable quality level (AQL) for the item in question. |

Defined size

|

Select this option so that the sample to be inspected may have a defined size. To do that, in the other fields, enter the desired specifications.

|

Control time frequency

|

Check this field to determine that the tests will occur in a certain frequency during item production. To do that, enter the frequency of its occurrence. If this field is not enabled, the system will not perform a test control in this characteristic.

|

Specification data

|

Test time

|

Use this field to enter the test duration time. Select also the measurement unit of the previously entered value.

|

Rel. humidity

|

Enter the relative humidity of the air in the environment in which the item sample will be during the test. Select also the measurement unit of the previously entered value.

|

Test temperature

|

Enter the temperature of the environment in which the item sample will be during the test. Select also the measurement unit of the previously entered value.

|

Atmospheric pressure

|

Enter the atmospheric pressure of the environment in which the item sample will be during the test. Select also the measurement unit of the previously entered value.

|

Retest rule

|

When the test is rejected, the system will request a new test. If the retest is rejected, define the decision to be made:

Note: This configuration will only be possible if the sampling rule is of the "Defined size" type.

|

Retest result

|

Rejected: The system will not generate a new retest and the test result will be "failed".

New test: If the test is rejected, the system will generate a new retest until it is approved.

|

# of samples

|

Number of samples that will be inspected during the retest.

|

Unit

|

Measurement unit of the reading of the retest sample characteristics.

|

Specification/sample/test attributes

Tab

|

Specification attributes

|

Associate the attributes that must be used as a reference during the item testing (SE Inspection).

|

Sample attributes

|

Associate the attributes that must be used when creating the sample.

|

Test attributes

|

Associate attributes that must have their respective values entered during testing (SE Inspection).

|

To do that, click on the  button and add the desired attributes. button and add the desired attributes.

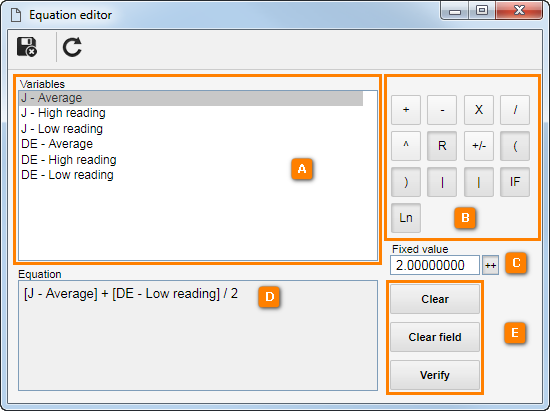

Equation

In production inspection, some characteristics are the result of an equation made with data from other characteristics to be inspected. Thus, in this section, configure equations using the item characteristics (control characteristics) as variables, or use a characteristic created specifically for the equation.

To build an equation, first, click on the  button and execute the following procedure: button and execute the following procedure:

1.Double-click on the desired variable (A). The selected option is displayed in the Equation (D) field. 2.If needed, click on the variable just once and assign a Fixed value (C) to it. Click on the ++ button (C) to add this value to the equation. 3.After that, select one of the operations (B) that, like the variable, will be displayed in the Equation (D) field. 4.Repeat this procedure until the Equation (D) is complete. 5.Use the Verify (E) button to check out the equation, Clear field (E) to start a new equation or just Clear (E) to delete the last data reported. 6.Save the record after building the whole equation. |

|

Save the record after filling out or editing the fields.

|