|

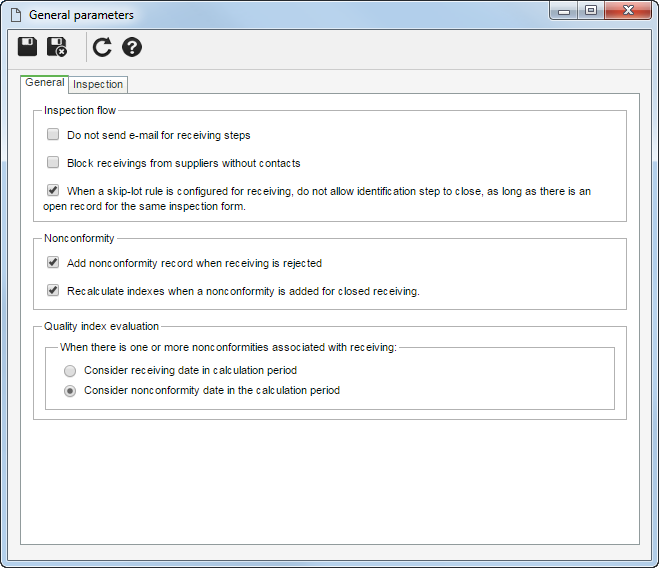

In order to configure the general parameters, access the Configuration  General parameters menu and fill out the following information on the screen that will be displayed: General parameters menu and fill out the following information on the screen that will be displayed:

Inspection flow

Quality index evaluation

|

Do not send e-mail for receiving steps

|

When enabled, it disables e-mail notifications for receiving steps.

|

Block receivings from suppliers without contacts

|

When enabled, it will not be possible to add receivings from suppliers that do not have recorded contacts. If it is disabled, it will be possible to add item receivings from any supplier.

|

When a skip-lot rule is configured for receiving, do not allow identification step to close, as long as there is an open record for the same inspection form

|

When enabled, the receivings of the same inspection form that are in progress must be finished before the identification step of the new receiving is closed. Otherwise, it will be possible to close new receivings even if previous receivings of the same inspection form are still unfinished.

|

Nonconformity

Parameter

|

Enabled

|

Disabled

|

Add nonconformity record when receiving is rejected

|

It makes associating a nonconformity record mandatory if the receiving is rejected in the RELEASE step. In this case, you will not be able to close the step unless there is at least one nonconformity related.

|

The closure can be performed without the need for associating nonconformities, even if the receiving is rejected.

|

Recalculate indexes when a nonconformity is added for closed receiving

|

Check this option so that the system recalculates the month-to-month indexes of the receiving until the last period if the receiving (analysis) associated with the nonconformity is part of an already calculated quality index.

|

The indexes will not be recalculated when adding nonconformities to a closed receiving.

|

Quality index evaluation

|

When there is one or more nonconformities associated with the receiving

|

▪Consider receiving date in calculation period: The system will consider the receiving date for the calculation when there are nonconformities associated with the receiving. ▪Consider nonconformity date in the calculation period: The system will consider the date of the nonconformities in the calculation period when there are nonconformities associated with the receiving. |

Fields required in production inspection

|

PO/SO #

MO #

Lot #

|

Check which of these fields must be filled out during a production inspection.

|

|

PPM calculations

|

Calculate based on the size of the lot

|

The PPM (parts per million) calculation will be based on the size of the lot.

|

Calculate based on the number of samples inspected

|

The PPM calculations will be based on the number of inspected samples

|

Consider defective items entered in nonconformity record to calculate PPM

|

The defective items reported in the records of nonconformity will be considered in the PPM calculation. If this option is not selected, the defective items reported in the nonconformity record will not be considered in the PPM calculation.

|

Parameter

|

Enabled

|

Disabled

|

Applicable switching rules

|

Check this option to use the switching system and so change the inspection type (normal, tightened or reduced) for another. It will only be possible to switch from tightened to reduced or vice versa, with the condition of first switching to normal inspection.

|

If this option is disabled, the system will not perform any sort of switching rules automatically. To do that, if necessary, the user will have to manually perform the switching of the inspection type in the inspection form of the item, processes or supplies.

|

Quality level

|

The inspection of items, processes or supplies can be changed by the system based on the lots received and rejected, according to the rules defined for the switching:

|

Normal to Reduced

|

If among 10 delivered lots none is rejected, the inspection type becomes Normal. It is possible to edit these values.

|

Reduced to Normal

|

If a lot is rejected, it passes to Normal inspection. It is possible to edit these values.

|

Normal to Tightened

|

If among 5 consecutive lots 2 have been rejected in the original inspection, the inspection type becomes Tightened. It is possible to edit these values.

|

Tightened to Normal

|

If among 5 consecutive lots all have been approved, the inspection type becomes Normal. It is possible to edit these values.

|

Stop inspection if ___ lots have been rejected due to tightened inspections

|

Enter the quantity of lots that will cause the inspection to be interrupted if reached.

|

The inspection types considered by the system are:

▪Normal: It is used when there is no evidence that the quality of the product considered is worse or better than the specified quality level. It is put into practice at the beginning of the switching rules. ▪Tightened: It is used when it becomes clear that the product quality is deteriorating. This inspection type requires greater attention in the acceptance criteria for quality control. Comments: In the case of improvement in product quality, it is allowed to return the inspection to normal. ▪Reduced: It is used when it becomes clear that the product quality is improving; therefore, it requires a smaller sampling for inspection. To restore the default values recommended by the Brazilian standards of applicable switching rules, click on the  button. button.

|

Gage association during inspection

Parameter

|

Enabled

|

Disabled

|

Use only gages checked out for usage

|

It will only be possible to associate gages that are checked out for usage with the inspection.

|

gage recorded in SE Asset may be selected in the inspection if the "Use only gages checked out for usage" option has not been selected.

|

Use only updated calibrated gages

|

It will only be possible to associate gages whose calibration is up to date with the inspection.

|

gage recorded in SE Asset may be selected in the inspection if the "Use only gages checked out for usage" option has not been selected.

|

Require gage association during inspection of attribute characteristics

|

The association of a gage in the attribute characteristics inspection step becomes mandatory.

|

The association of gages during the inspection step will not be mandatory, allowing it to be closed without this information.

|

Require gage association during inspection of variable characteristics

|

The association of a gage in the variable characteristics inspection step becomes mandatory.

|

The association of gages during the inspection step will not be mandatory, allowing it to be closed without this information.

|

|

|