Disable characteristics in the production inspection

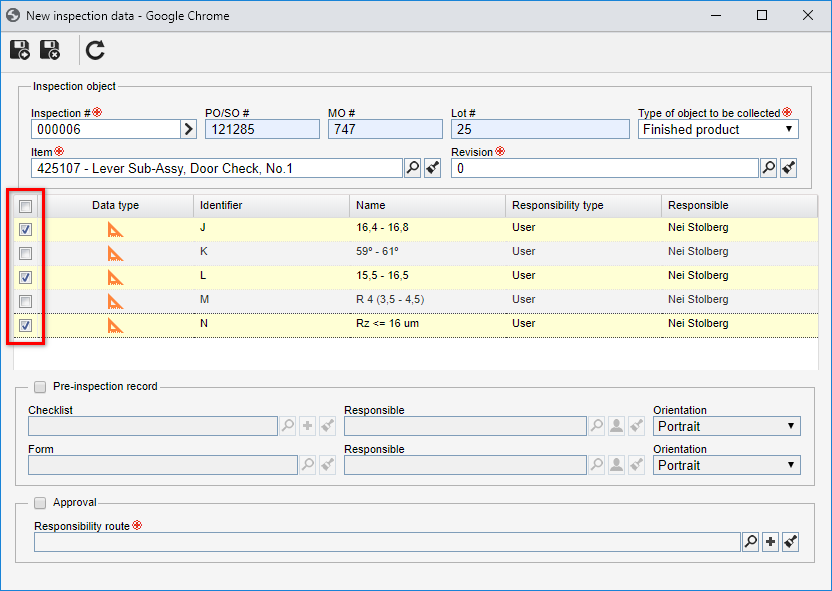

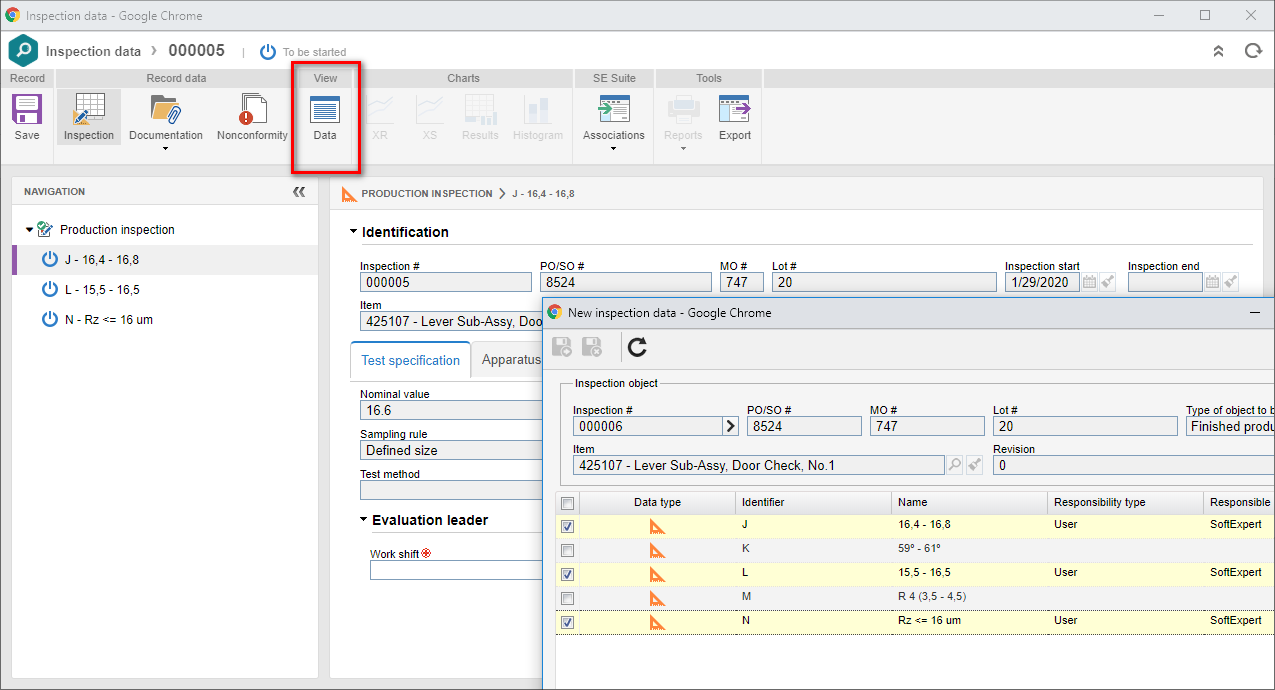

From this version onwards, it will be possible to define which characteristics will be part of the inspection during production. The characteristics defined for the item or for the process activity will all be displayed when creating the inspection, but it will be possible to disable them, creating the inspection only with the characteristics that remain selected. On the upper menu in the inspection data screen, it will be possible to view which characteristics were originally part of the item or process activity, ad which have been disabled.

Approval step in the production inspection

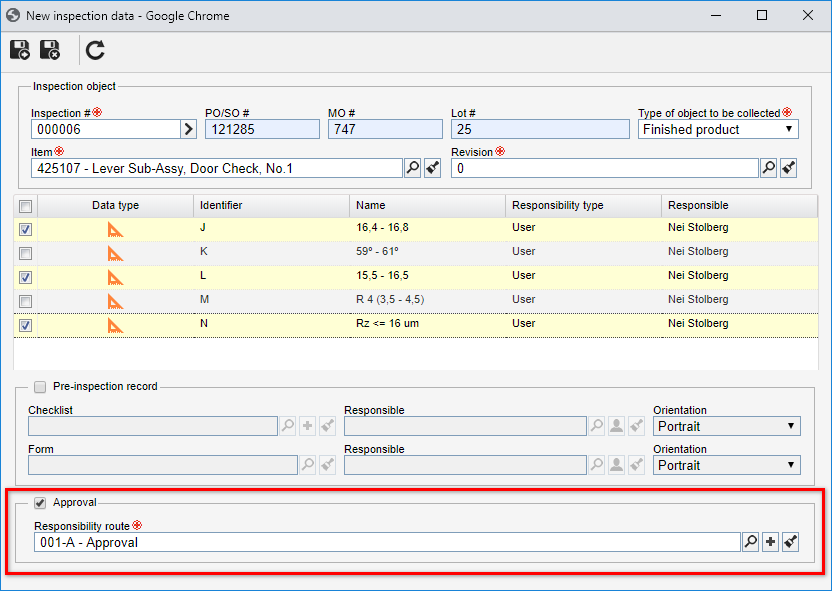

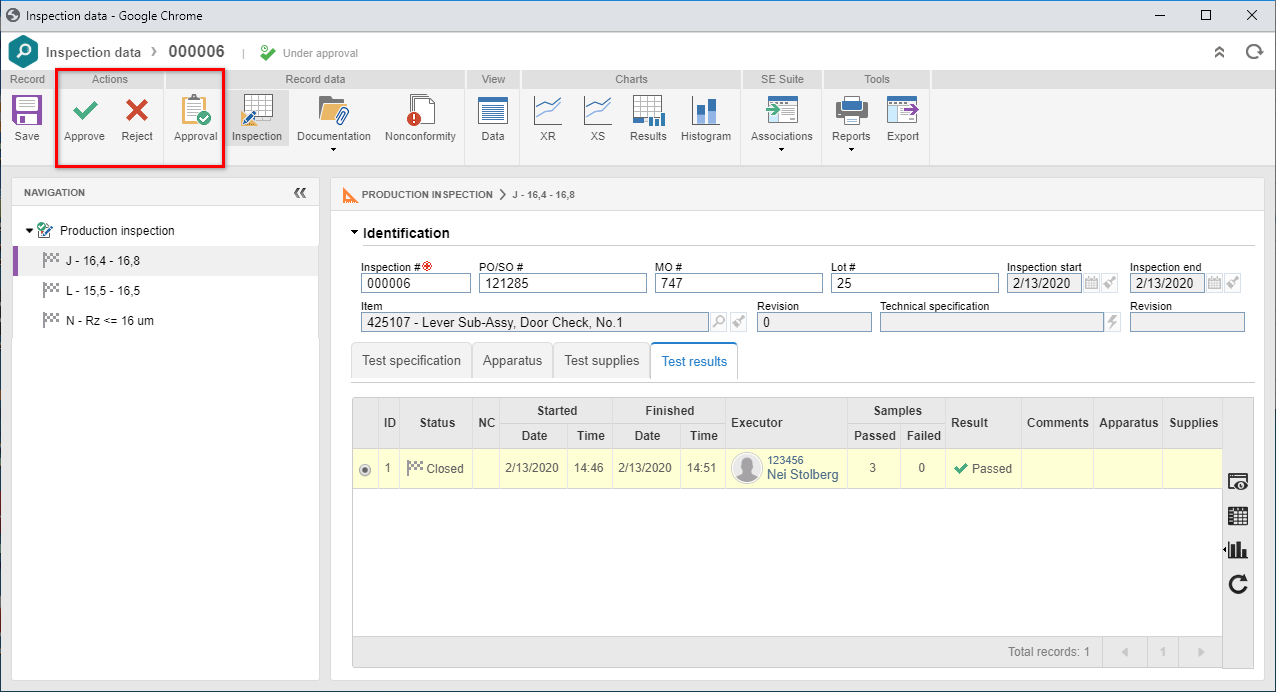

In this version, the production inspections can be sent to an approval step in which a user, team or department will analyze the inspection, returning it to execution if necessary.

In the approval step, it will be possible to adjust the inspection number, production order number, manufacturing order number and/or batch.

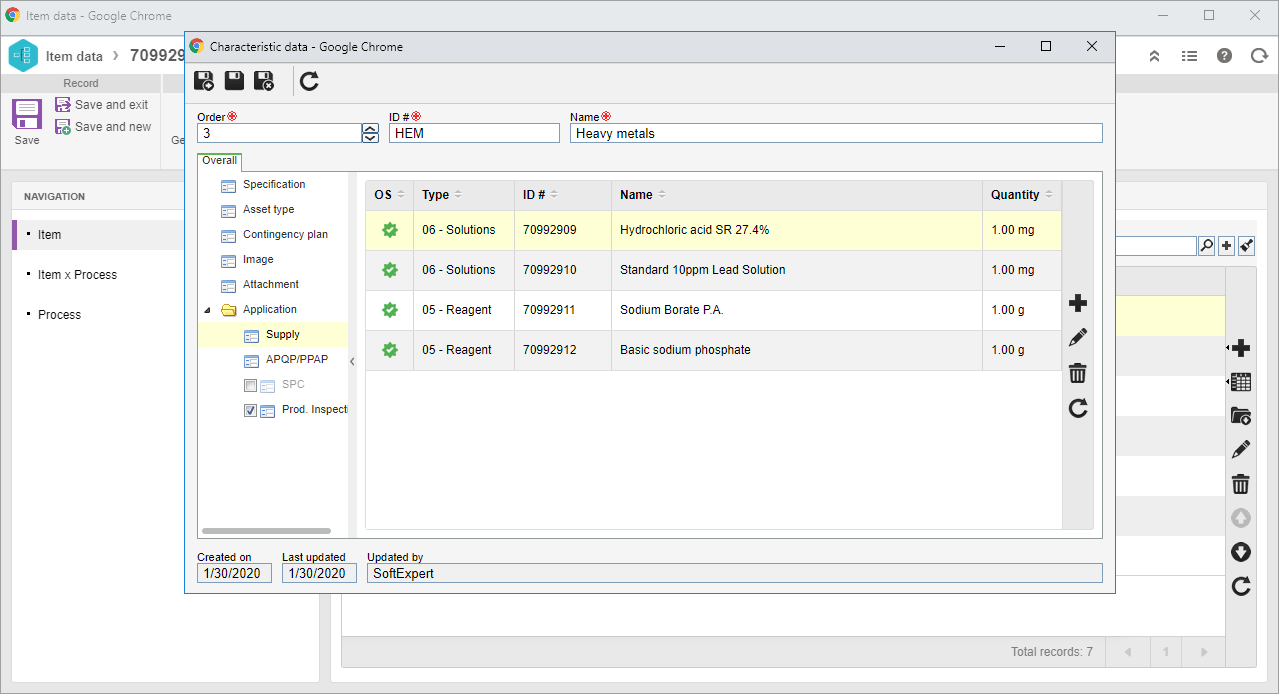

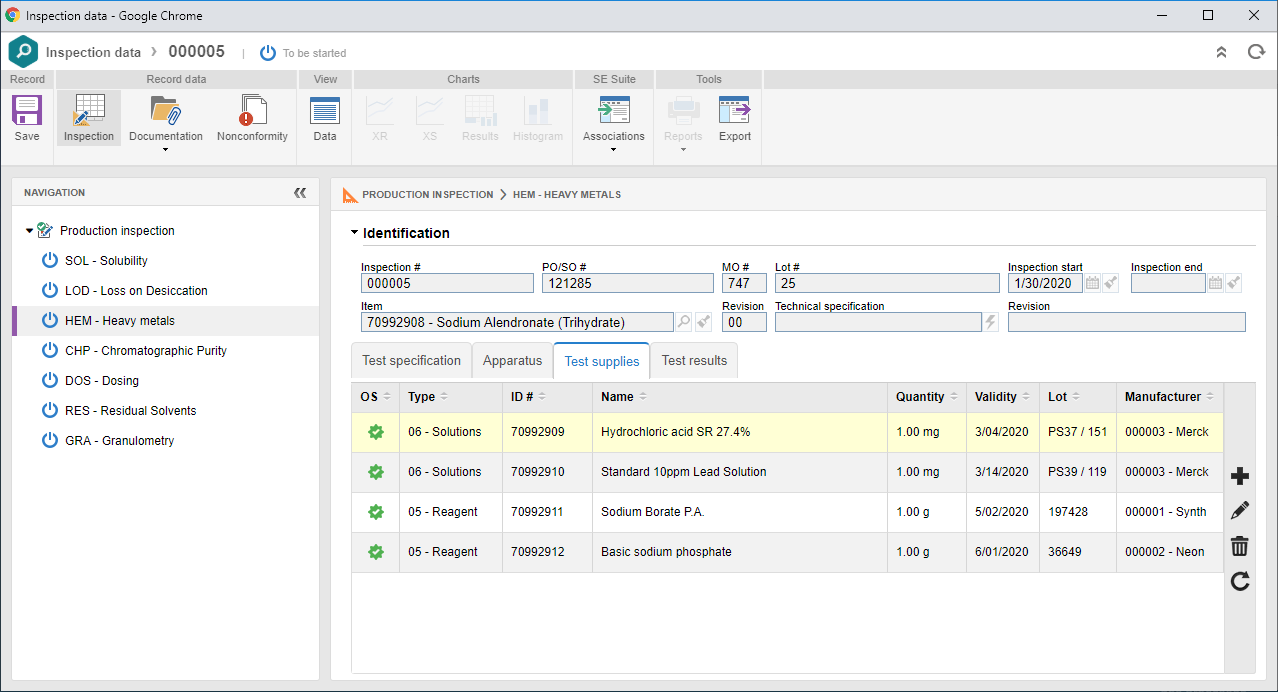

Supply relationship in the production inspection characteristic

Materials used to perform the tests can now be associated with the item characteristics, composing a relationship of supplies used during the production inspection tests. Furthermore, it will be possible to enter the validity of the material that was used, its respective batch number and its manufacturer. The information set in the characteristic will be displayed in the test supply screen, but they may be edited as necessary.

Previous versions

View also the improvements made to this component in previous versions: